Alumina ceramic foam filter for aluminium melt filtration is the last process in the purification of aluminium casting, and it is also a crucial link.

Ensuring the cleanliness of the aluminum melt cannot be ignored. It needs to be particularly pointed out that the secondary pollution of the melt that may occur during the solidification and molding process of the aluminum melt after the aluminum melt leaves the filter box must be prevented. In this process, ceramic launders, front boxes, and casting platforms are used, and dehumidification and cleaning are performed in time to eliminate possible sources of pollution.

The composition of the aluminum alloy alloys for different purposes is different. Before the profile extrusion, the aluminum profile needs to be melted and casted to match the purpose of the aluminum alloy rod.

The specific aluminum rod casting process is as follows:

1. Purchase of pure aluminum and aluminum ingots.

2. Alloy casting, melting the pure aluminum ingot in a melting furnace, then adding other alloy components, and then pouring it into the grinding tool to cool and shape to form the alloy aluminum rod to be extruded.

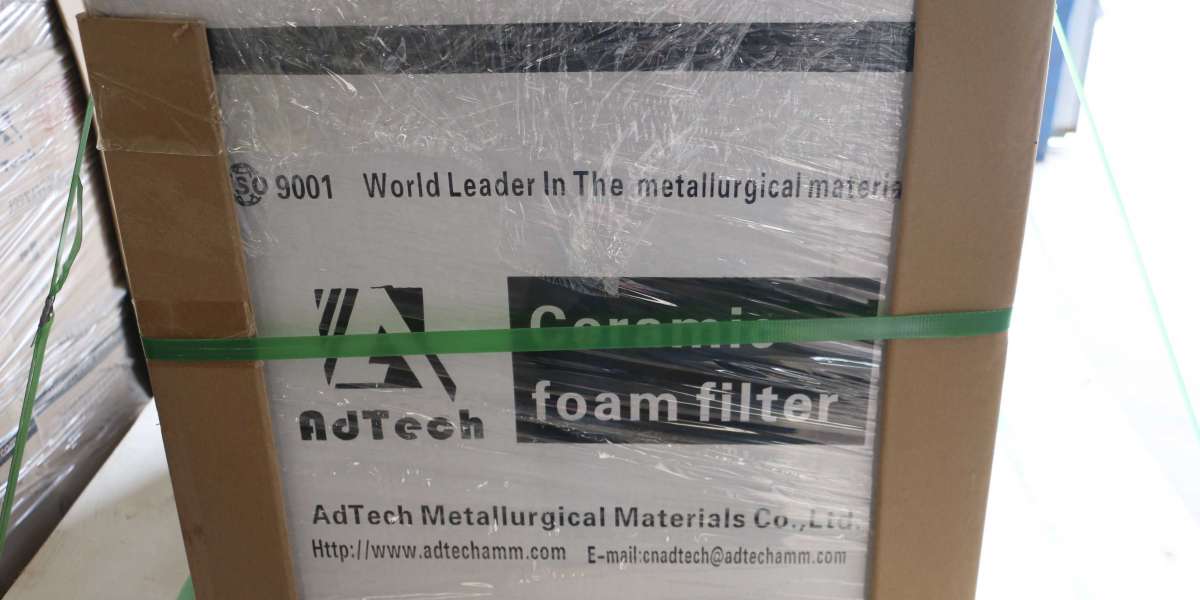

Alumina ceramic foam filter for aluminium melt filtration is a kind of porous ceramic product with opening porosity as high as 80-90%, with a unique three-dimensional network framework and interpenetrating pore structure.

The alumina foam ceramic filter plate filters and removes impurities, which can significantly improve the quality of ingots and reduce the waste rate. Since then, the corresponding research and development of foam ceramic filter materials have been promoted in the metallurgical industry.

The ceramic foam filter plate removes the non-metallic inclusions in the aluminum alloy melt and adopts the furnace flux treatment. The technology of the ceramic foam filter outside the furnace has long become an important method for the purification of molten aluminum.

The ceramic foam filter mechanism is generally described as diffusion interception and inertial collision interception or screening, sedimentation and deep bed filtration.