Flux for Melting Aluminium is a solid substance (usually a mixture of chloride and fluoride salts) used in aluminum foundries to reduce melt oxidation, minimize the penetration of atmospheric hydrogen, and absorb non-metallic inclusions suspended in the melt keep furnace/ladle walls clear of built-up oxides, reduce entrained aluminum content in aluminum slag, remove dissolved hydrogen in the melt, refine aluminum grains during solidification, modify silicon inclusions in silicon-containing alloys, oxidizing excess magnesium.

In the smelting process of aluminum and aluminum alloys, hydrogen and oxide inclusions are the main substances that pollute the aluminum melt. Aluminum easily forms Al2O3 or secondary alumina (Al2O and A10) with oxygen, and also easily absorbs gas (H), which accounts for 70-90% of the total gas in the aluminum melt.

The main defects of cast aluminum alloys are caused by solid particles such as pores and slag inclusions. Therefore, in order to obtain high-quality melt, it is not only necessary to choose the correct and reasonable smelting process, but also the refining and purification of the melt are very important.

Granular flux is a new, efficient and environmentally friendly additive. It is used in the secondary refining process of aluminum alloy smelting and aluminum alloy casting. Hydrogen content, reduce aluminum loss.

Different from traditional powder flux, granular aluminum alloy flux has obvious technical advantages and economic benefits. At the same time, in the process of reacting with the aluminum melt, the gas released by the granular flux is non-toxic and has little exhaust gas, which greatly improves the production environment.

Based on the above advantages, granular aluminum alloy fluxes have attracted more and more attention in the industry, and have a tendency to gradually replace traditional powdered fluxes.

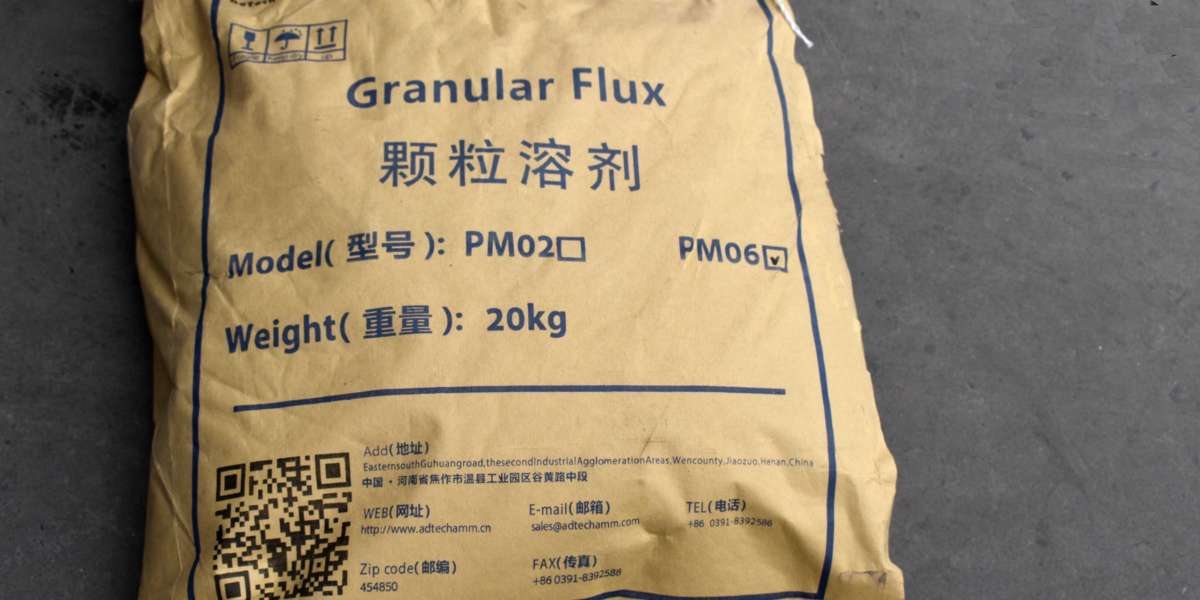

AdTech granular flux for melting aluminium has two specifications of PM02 and PM06. It is white (slightly gray) granular. It adopts unique technology to effectively improve the effect of degassing, slag and alkali metal removal from molten metal.