Degassing Units Definition

AdTech is an enterprise specialized in new material development and high precision online degassing unit production since 2012, got positive feedback from domestic and overseas market.

Degassing Units Definition

Degassing Units adopt advanced high silicon melting technology to get a long service time, degassing rotor, heater protection thimble and thermocouple protection thimble adopt ceramic manufacturing technology which can meet producing high-precision aluminum requirements.

Online degassing unit shall be installed between furnace and casting equipment. It is used for hydrogen (H) and slags removal from molten aluminum. The online degassing unit has dual functions: processing and heating. It serves high precision molten aluminum purification industry.

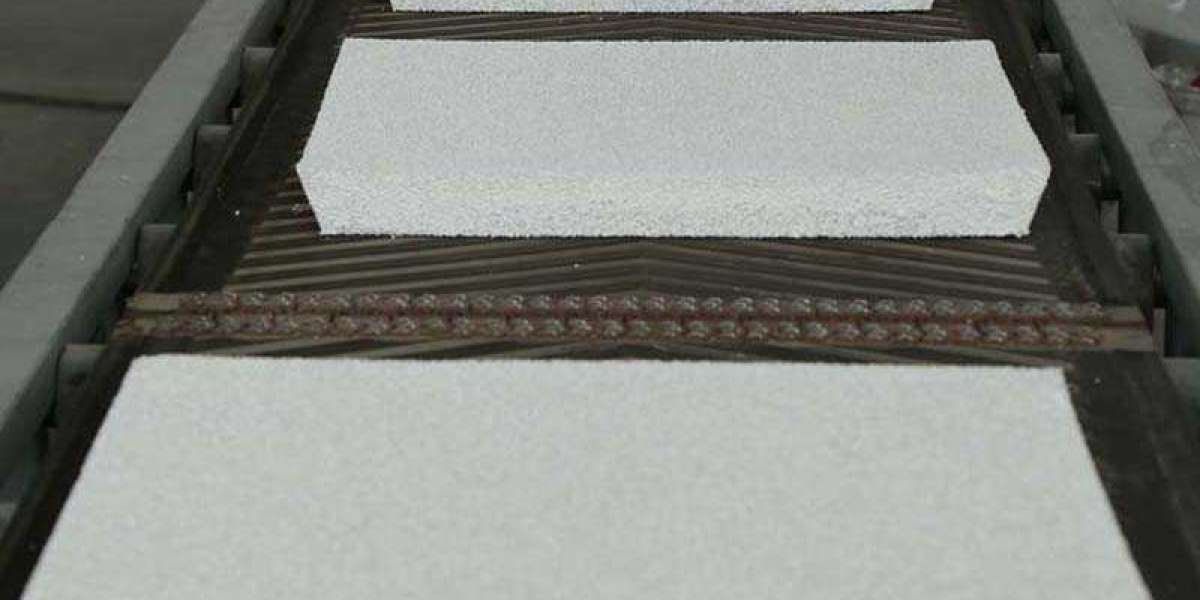

Assembling of Online Degassing unit

Mechanical Drive

Degassing Box Cover

Rotor Heater

Electric Control

Degassing Units Advantages And Benefits

High degassing efficiency

The design of the rotary degassing allows the small bubbles to diffuse sufficiently in the aluminum liquid. The contact surface of the bubble and the aluminum liquid is increased, and the degassing efficiency of the device is improved.

Low cost of use

It reduces the power consumption during the use of the equipment; the advanced graphite rotor design reduces the consumption of working gas and secondary pollution caused by eddy currents.

Easy to use

It adopts flexible design and is suitable for various casting methods, which greatly facilitates the progress of other processes and can improve production efficiency.

Small footprint, flexible operation: easy to use, especially suitable for poor conditions in the workshop, which can reduce the amount of infrastructure work during equipment renovation.

Simple maintenance

The manufacturer fully considers the user maintenance cost, the main control components use imported components, and at the same time use standard parts as much as possible to facilitate user maintenance and replacement.